The hybrid workplace is a concept on the lips of every industry trend in the world today. Every workplace needs to maximize and transcend obstacles and innovations to ease into the hybrid workplace. The COVID-19 pandemic brought a wave for an increased need for a hybrid workplace (Iqbal et al., 2021). Future places for learning and working are digitally and physically integrated hybrid environments (Lahti et al., 2021).

Digitalization and Industry 4.0 have been frequently used in recent years. According to Gartner Glossary, digitalization is the use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business. However, the key is that implementing related technologies can sustainably empower people and daily operations (Leyer et al., 2019). It is a grand challenge of any successful implementation project to improve current and future work practices of employees (Richter et al. 2018). This requires an integrated, interdisciplinary, participative, and agile approach, which allows identifying, analysing, and supporting human work practices in a predominantly digital environment (Spitzer et al., 2020).

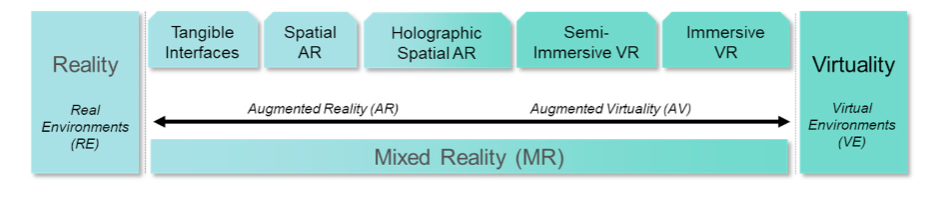

Both Augmented Reality (AR) and Mixed Reality (MR) technologies have a long history, it was first introduced in the 1990s towards the implementation of a heads-up, see-through, head-mounted displays in manufacturing (Caudell et al., 1992). However, recent technological advancements of wearable technology devices have not only increased in usability, but also increased adoption of AR and MR technologies in industrial worker-centric use cases (Spitzer et al., 2020). A comprehensive framework is first given through the reality-virtuality-continuum shown in Fig. 1 (Milgram et al., 1994).

In manufacturing, MR is increasingly utilized for information visualization, remote collaboration, human-machine-interfaces, design tools and education and training (Quint et al., 2015). This development makes new demands on learning factories in two major fields: One is the empowerment of users to work with MR in industrial applications. The second field is the utilization of the potential of MR for teaching and learning in learning factories (Juraschek et al.,2018). MR can enable learners to take control of their training and learning speed (Thiede et al., 2017) and can be utilized to motivate learners on a specific topic (Stratos et al.,2016). By providing information at the right time and space, it can improve the efficiency of education and training (Lee, 2012). In the context of the digitalization of manufacturing and movements such as “Industrie 4.0”, MR becomes a vital part of learning environments (Guo, 2015).

There is evidence assessing the application of MR technologies in manufacturers and its contribution to hybrid workplaces in the industry globally. The concept of MR based Learning Factory has been adapted by appliance manufacturers with five factories located in ANZ, Asia, Europe, and North America. Thus, despite this early adaption, it provides a valuable framework for exploration in adapting to other use industries.

AlphaPi aims to discover the motivation from the industry to tailor our MR technologies to those needs. We conduct case by case workshops to extract the domain knowledge from the Subject Matter Experts and leverage our technical experience to build a solution.

Objectives

- To understand the industries framework, including its processes, operations, culture, management, trends, and its competitive advantage

- To understand the underlying problems that are derived from those in (1) including, dangers, failures, risks, and losses (such as human loss, financial loss)

- To understand the decisions that need to be made that can lead to the problems in (1)

- To determine a framework that adapts MR technologies to assist in the decisions defined in (3) resolving the problems in (2) and aligns to the industries framework determined in (1)

- To build, trial and pilot the MR technologies within the framework determined in (4) in the real-world environment with the end-user

- To determine a feedback pipeline in (5) that allows optimizing the framework for alignment with (4)

- To discover a method that generalizes (4)-(6)

Reference

- Iqba, K. M. J., Khalid, F., Barykin, S. E.(2021) Hybrid Workplace: The Future of Work. Handbook of Research on Future Opportunities for Technology Management Education

- Lahti, M., Nenonen, S. P.(2021) Design Science and Co-Designing of Hybrid Workplaces

- Leyer, M., Richter, A., Steinhüser, M. (2019) “Power to the workers”: empowering shop floor workers with worker-centric digital designs. Int. J. Oper. Prod. Manag 39(1), 24–42. https:// doi.org/10.1108/IJOPM-05-2017-0294

- Richter, A., Heinrich, P., Stocker, A., Schwabe, G. (2018) Digital work design – the interplay of human and computer in future work practices as an interdisciplinary (grand) challenge. Bus. Inf. Syst. Eng. 60(3), 259–264

- Spitzer, M., Rosenberger M., Stocker A., Gsellmann I., Hebenstreit M., Schmeja M. (2020) Digitizing Human Work Places in Manufacturing Through Augmented and Mixed Reality. Digital Transformation in Semiconductor Manufacturing. DOI: 10.1007/978-3-030-48602-0_8

- Caudell, T.P., Mizell, D.W. (1992) Augmented reality: an application of heads-up display technology to manual manufacturing processes. In: Proceedings of the Twenty-Fifth Hawaii International Conference on System Sciences, 7–10

- Milgram, P. and Kishino, F. (1994) A Taxonomy of Mixed Reality Visual Displays. IEICE Trans. Inf. Syst., vol. E77–D, no. 1

- Quint, F., Sebastian, K., and Gorecky, D. (2015) “A Mixed-reality Learning Environment,” Procedia Comput. Sci., vol. 75, no. Vare, pp. 43–48

- Juraschek, M., Büth, L., Posselt, G., Herrmann, C. (2018) Mixed Reality in Learning Factories. Procedia Manufacturing. DOI: 10.1016/j.promfg.2018.04.009

- Thiede, B., Posselt, G., Kauffeld, S.and Herrmann, C. (2017) Enhancing Learning Experience in Physical Action-orientated Learning Factories Using a Virtually Extended Environment and Serious Gaming Approaches. Procedia Manuf., vol. 9, pp. 238–244

- Stratos, A., Loukas, R., Dimitris, M., Konstantinos, G., Dimitris, M. and George, C. (2016) A Virtual Reality Application to Attract Young Talents to Manufacturing. Procedia CIRP, vol. 57, pp. 134–139

- Lee, K. (2012) Augmented Reality in Education and Training. TechTrends, vol. 56, no. 2, pp. 13–21

- Guo, Q. (2015) Learning in a Mixed Reality System in the Context of ‘Industrie 4.0,’. J. Tech. Educ., vol. 3, no. 2, pp. 92–115