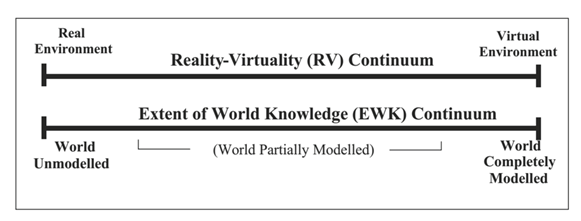

MR is a subset of (VR) related technologies that involve the merging of real and virtual worlds somewhere along the “virtuality continuum” which connects completely real environments to completely virtual ones (Milgram and Kishino, 1994). Reality-Virtuality Continuum is shown in the figure below (Milgram and Colquoun, 1999):

An early survey defines AR as a variation of VR. While the user is fully immersed in VR and cannot see the real world around him, AR allows the user to see the real world with virtual objects superimposed upon or composited with the real world. AR applications include health, manufacturing and repair, annotation and visualization, robot path planning, entertainment, and military air crafts (Azuma, 1997). One definition states that an AR system combines real and virtual objects in a real environment, runs interactively, and in real time; and registers (aligns) real and virtual objects with each other (Azuma et al., 2001).

A more recent survey of AR technologies indicated the extension of its applications including some more prominent fields, such as, personal information systems, industrial and military applications, medical applications, entertainment, collaboration, and education and training (van Krevelen et al., 2010). Recently, Billinghurst et al., 2015 listed education, architecture, and marketing as prominent examples of typical modern-day applications for AR.

Mixed reality (MR) applications are increasingly deployed in industrial practice. In manufacturing, MR can be utilized for information visualization, remote collaboration, human-machine-interfaces, design tools and education and training (Juraschek et a1., 2018). A great potential of MR in the context of manufacturing lies in assistive environments that includes training and learning and on the job support (Büttner et al., 2017).

Today, MR technology is applied in learning factories, the “blended learning” and “virtual learning factories” are recognised as innovative competency development approaches (Abele et al. 2017). MR can enable learners to take control of their training and learning speed (Thiede et al., 2017) and can be utilized to motivate learners on a specific topic (Stratos et al.,2016). By providing information in the right time and space it can improve the efficiency of education and training (Lee, 2012). In the context of the digitalization of manufacturing and movements such as “Industrie 4.0”, MR becomes a vital part of learning environments (Guo, 2015).

The rise of new digital industrial technology known as Industry 4.0 is a transformation that recognises Augmented reality (AR) as one of the nine foundational technologies (See Fig. 3) . (Rüßmann, et al., 2015).

Mixed reality can be assessed under a six-parameter Mobile Collaborative Learning (MCL) framework. The assessment includes Perceived Usefulness (PU), Perceived Ease-of-Use (PEOU), User Satisfaction (US), Affective Domain (AF), Cognitive Domain (CO) and Perceived Enjoyment (PE). Perceived Usefulness (PU) and Perceived Ease-of-Use (PEOU) are defined according to the Technology Acceptance Model (TAM) (Davis, 1989). The former concept is associated with user perception in terms of value, while the latter is more related to usability. The third criterion, User satisfaction (US), reflects the quality of experience. The affective domain (AF) addresses feelings and, more in general, the emotional area. The impact on the cognitive domain (CO) considers mental skills, and it is indeed related to learning performance and motivation. Finally, perceived enjoyment (PE) aims at measuring the enjoyment of learning. (Alyami et al., 2020)

References

- Abele E. et al. (2017) Learning factories for future oriented research and education in manufacturing. CIRP Ann. – Manuf. Technol., vol. 66, no. 2, pp. 803–826.

- Alyami, A., Pileggi, S. F., Hawryszkiewycz I. (2020) The Impact of New Technologies on Learning: A Literature review on Mobile Collaborative Learning. Pacific Asia Conference on Information Systems (PACIS)

- Azuma, R. (1997): A Survey of Augmented Reality. Teleoperators and Virtual Environments 6, 4, 355–385

- Azuma, R, Baillot, Y, Behringer, R, Feiner, S, Julier, S, MacIntyre B. (2001) Recent advances in augmented reality. IEEE Comput. Graph. Appl. https://apps.dtic.mil/dtic/tr/fulltext/ u2/a606245.pdf

- Billinghurst, M., Clark, A., Lee, G. (2015) A survey of augmented reality. Found. Trends® Hum.– Comput. Interact. 8(2–3), 73–272 (2015). https://doi.org/10.1561/1100000049

- Büttner S. et al., (2017) The Design Space of Augmented and Virtual Reality Applications for Assistive Environments in Manufacturing. A Visual Approach,” Proc. 10th Int. Conf. Pervasive Technol. Relat. to Assist. Environ., pp. 433–440.

- Davis, F. D. (1989) Perceived Usefulness, Perceived Ease of Use, and User Acceptance of Information Technology. MIS Quarterly: Management Information Systems (13:3), pp. 319–339. (https://doi.org/10.2307/249008).

- Milgram, P., Colquhoun, H. (1999). A taxonomy of real and virtual world display integration. In: Ohta, Y., Tamura, H. (eds.) Mixed Reality, no. 418, pp. 5–30. Springer-Verlag Berlin, Heidelberg. https://www.springer.com/de/book/9783642875144

- Rüßmann, M., Lorenz, M., Gerbert, P., Waldner, M., Engel, P.l ., Harnisch, M. and Justus, J. (2015) Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. Google Scholar

- Van Krevelen, D.W.F., Poelman, R. (2010) A survey of augmented reality technologies, applications and limitations. Int. J. Virtual Real. 9(2), 1–20